Sublimation has revolutionized the way of making long – lasting, vibrant designs on the apparels, but printing natural fabric like cotton is challenging. Generally, this method works best with synthetic materials like polyester or poly blends, but it’s hard to print on cotton.

When I began my sublimation journey, I was so disappointed to figure out that cotton fabric cannot be sublimated. Because I like to wear cotton. It’s so comfy. Since then, I kept experimenting and now I have 4 methods by which sublimating cotton fabric is possible. Do you want to know how? Keep reading.

Is it possible to sublimate cotton?

Yes, you can easily sublimate cotton, but not in a traditional way. Unlike polyester fabric, cotton don’t accept sublimation dye naturally. But with the help of special coatings, it is possible to print cotton. This innovative solution creates a receptive layer on the cotton surface for holding the ink, providing a successful transfer of long – lasting, vibrant prints.

Issue in sublimating cotton fabric

The fibers of cotton do not absorb sublimation ink due to which you will never get fade – resistant and permanent prints. So, direct sublimation on cotton fabric is not possible. There are many alternatives which I have found by experimenting and researching. Let’s explore!

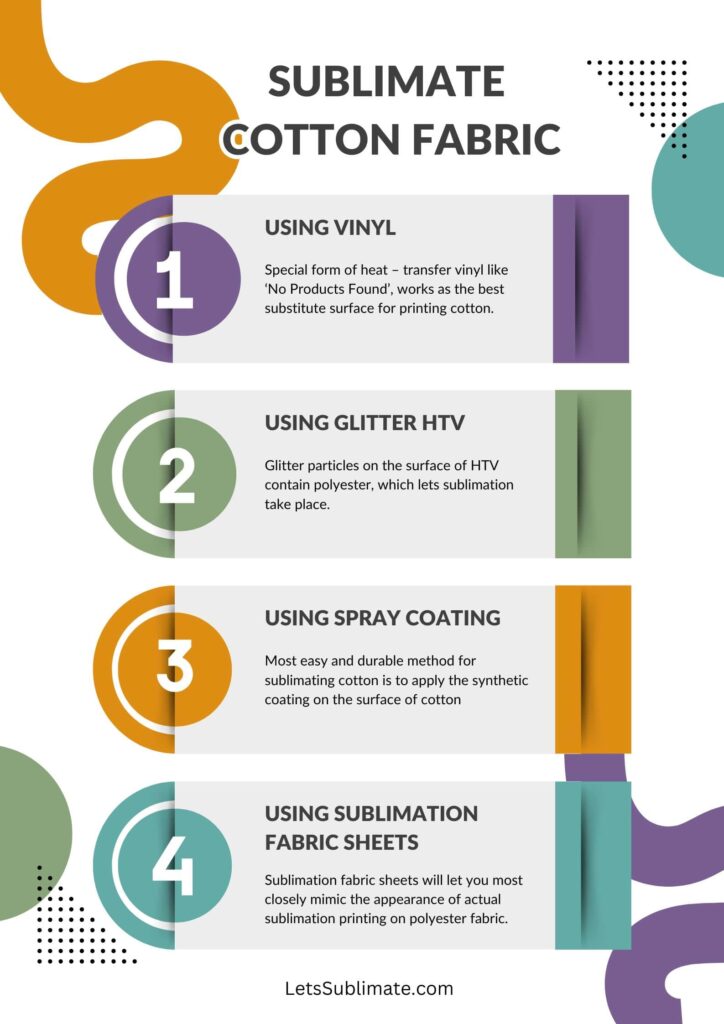

4 Methods to sublimate cotton

With multiple attempts I came to a conclusion that you can use below four workable methods for printing cotton material. These are.

1. Using Vinyl

Special form of heat – transfer vinyl like ‘No Products Found’, works as the best substitute surface for printing cotton. It is important to remember that you cannot simply sublimate the HTV. With this process you always have to find the right surface which contains polyester for the ink bonding process. Follow the process below.

- Make a digital design using any graphic design software.

- Print this design directly on the vinyl. Make sure to use the best ink for great results.

- Now insert this design in cutting machine for cutting the outline of the design.

- After this you need to weed away excess vinyl.

- Mask the vinyl using the squeegee for gently applying the clear masking sheet. It will allow you to lift the design and place it on the cotton substrate. Make sure to properly align the vinyl on the shirt.

- Now place the Teflon sheet on the top of the design to protect it during heat press.

- Set the heat machine to 311℉. (lower temperature is required due the use of vinyl surface).

- Finally press the design for only 15 seconds.

With this method you will get amazing prints, but you may feel the design is a little bit raised and stiff due to the usage of vinyl.

2. Using glitter HTV

The cool thing about this process is that little glitter particles on the surface of HTV contain polyester, which lets sublimation take place.

- Initially you need to make and download the design in SVG format.

- Mirror the artwork so that it doesn’t end up backward.

- Using a cutting machine, cut it out and weed out the excessive vinyl.

- Apply the glitter vinyl to the cotton substrate by following the instructions mentioned on vinyl packaging. Here you have to use the heat press to seal the vinyl on cotton at 400℉ for 60 seconds.

- When the cotton cools you can now move on the sublimation part of this process (if not done already). Print the design on the transfer paper.

- Place this transfer paper in a way that it aligns perfectly with the vinyl cut – out on the cotton. Use the heat safe tape to keep your design in place.

- Again set the heat machine to 400℉ for 60 seconds.

- Now you have the glittery, colorful design on the cotton substrate.

The only downside of this process is that you need to work on an additional step of cutting and weeding the vinyl before printing the design on substrate. However, the winning situation is that you can use this process on both light and dark color shirt.

Also, if you wish to make the complicated design from HTV then you would need to cut multiple pieces of each color of vinyl. In this way you can simply apply the dye on white glitter vinyl for achieving multicolored artwork.

3. Using spray coating

The most easy and durable method for sublimating cotton is to apply the synthetic coating on the surface of cotton and then follow the steps of sublimation.

This process used two applications of the spray. First removes the sizing from the substrate and another creates the synthetic surface for the transfer of artwork. Here is the procedure.

- Begin by spraying the cotton fabric thoroughly until you feel damp to touch.

- Set the heat machine to 330℉ and place the substrate.

- Spread the parchment paper on the top of the damp shirt and press for 30 seconds. Steam will come out of the press and spray removes the sizing from the cotton piece.

- Now apply the second coat of same spray on the substrate and again put it in heat machine at 330℉ for 30 seconds. This is to seat the coating. After this you will feel the plasticky surface on the substrate.

- Place the butcher or parchment paper beneath the cotton shirt and then align the transfer paper on the top of the substrate. Then place another butcher or parchment paper on top of it to protect the heat machine.

- Now set the heat press at 385℉ and press for 70 seconds to allow the sublimation to take place.

The only problem you are going to face with this process is that the spray coating will attract dust and this dust will create a mark on the final outcome. So, it is important to work in a dust free environment.

4. Using printing fabric sheets

These fabric sheets will let you most closely mimic the appearance of actual dye – sub printing on polyester fabric. These lightweight fabric sheets do not create the thick barrier like HTV, making it appear like the ink has actually sunk in the cotton fabric.

Additionally using the special fabric sheet also does not require the complex cutting out process used in HTV. Here are the steps to follow.

- Make or download the bright colored vector design. Don’t forget to mirror the design before printing.

- Place the blank side of the fabric face down in the printer and then print the artwork.

- Prepare the substrate by pre – pressing it for 20 seconds. It will create a smooth and wrinkle free surface for the design.

- Align the printed fabric sheet with the substrate.

- Make sure to cover it with parchment paper or silicone pressing mat.

- Press this sandwich for 30 seconds in a heat machine at 365℉.

- Peel the transfer sheet away when it is still hot.

- Now apply the finishing paper immediately and press again for 30 seconds.

Here is one catch. While using the fabric sheets it is important to use very bright vector designs. They must have a CMYK color value of 150%(minimum). Also, you need bold and vivid colors for this process to show up well.

Conclusion

Sublimating cotton is not challenging as you can use above methods to print your favorite designs on cotton fabric. With some basic additional steps, you can easily showcase stunning designs on cotton. What do you think about it? Share your thoughts in comments or message me directly.

FAQs

Q- What is the optimal time and temperature settings for cotton sublimation?

The optimal time and temperature setting for cotton substrate may vary based on the specific HTV brand and the spray you use. However, the recommended temperature ranges between 300°F and 385°F (149°C and 196°C). And the pressing time can vary from 30 seconds to 120 seconds. But it is important to follow the manufacturer’s instructions for best results.

Q- How to sublimate on dark cotton substrates?

Printing dark cotton shirts includes some extra steps. Initially you need to use the light or bright colored HTV as the base to make sure the outcome is vibrant. Additionally apply the synthetic spray coating on the substrate to help ink to bond well.

Q- Can you sublimate on cotton material?

Yes, you can print on cotton substrates. There are four workable methods (mentioned above) to do so like HTV, coating spray etc.

Q- What is a sublimation coating spray?

The sublimation coating spray is the product specially designed to make a surface on cotton material which mimics the property of polyester. It allows the dye to permanently adhere to the fabric, allowing printing on cotton.

Q- How can I choose the right coating spray for cotton blanks?

While selecting the spray for cotton, it is necessary to consider the factors like compatibility with dye, ease of application, durability etc. Make sure to research multiple brands to get the best one.

Q- How to ensure longevity of the sublimated cotton?

For maintaining the longevity and quality of the printed substrate I recommend following proper care instructions. It includes washing shirts inside out using mild detergent and avoiding bleach or harsh chemicals. Also air dry it to maintain prints.

Q- Can you sublimate on cotton without special coatings?

You will not be able to sublimate pure cotton without using special coating. However, you can use poly blend fabric i.e. 60 – 70% polyester and 30 – 40% cotton for printing without coating.

Q- Will sublimation ink wash out of cotton?

Yes, if you try to sublimate untreated fabric, then it will probably wash out. It happens because synthetic sublimation dye is unable to chemically bond with the natural cotton fibers. However, you can sublimate on pure cotton by making a synthetic surface on top of fabric.