Sublimation process is a rewarding craft, but like any other art form you have to face some challenges while learning it.

I have spent countless days experimenting and mastering this art and trust me, I made multiple mistakes in my journey.

Whether you are a beginner or an experienced crafter looking to refine the skills, you can skip the frustration of failing and can learn from my 10 common mistakes mentioned below,

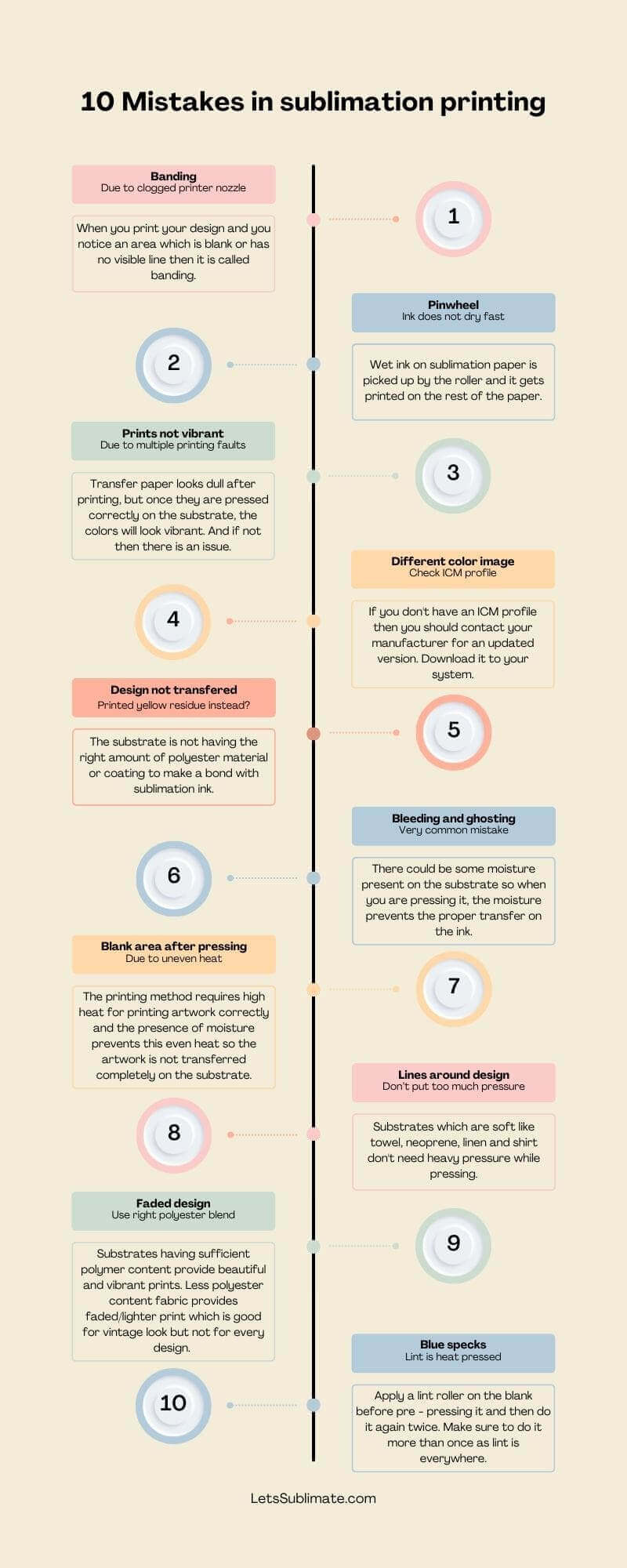

1. Banding

When you print your design and you notice an area which is blank or has no visible line then it is called banding.

It is formed by a clogged nozzle of the printer which does not let ink flow out while printing. The main cause is the dried ink in the print head, a clog in the line so that the ink does not reach to the print head.

Or it may be because of a ruined print head. It is always a good idea to use a printer regularly so that print heads remain working and ink does not dry up. For better performance you should use a self – maintenance printer, but if you don’t have it, just keep printing something once in a while.

If you have a regular sublimation printer, I recommend printing one transfer a week. And if the printer is unused for a long time, you should do a nozzle check before printing.

If the printhead pattern is missing any line then you may have to clean the printhead simply by printing a full page bleed for unclogging the lines.

After this you should run another nozzle check and if the same thing happens repeat the cleaning process and run one more nozzle check. If still you are seeing same issue then you have to clean the printhead with denatured alcohol.

2. Pinwheel on printed substrate

These are also known as pizza wheel marks or roller marks which are present on the sublimation paper in the form of dotted lines. They will get transferred to the substrate when they are pressed.

It is mainly caused when ink on the paper is not drying fast. The wet ink is picked up by the roller and it gets printed on the rest of the paper. So, make sure to use high quality paper which is compatible with your printer. Also, turn off high speed printing. It will slow down the printer and will allow some time for your ink to dry.

3. Transferred prints are not vibrant

If the sublimation paper receives dull prints then it can either be normal or a problem.

Normally transfer paper looks dull after printing, but once they are pressed correctly on the substrate, the colors will look vibrant.

But if the pressed images are still looking dull then it may be because of

- You may have printed on wrong side of the transfer paper. Many transfer papers have a watermark on the back side, so always make sure you are printing on the non watermarked side of the paper. But if you are working with paper which does not have any water mark then choose the brightest/whitest side to print.

- Make sure you are using high quality sublimation ink which is compatible with your printer and transfer paper.

- Missing ICM profile. Many ink manufacturers provide ICM profiles. So check and ensure you have downloaded it and you are working with the latest version.

- You are not working with high quality images as the images which are of low quality or small will result in poor quality prints.

4. Pressed image is of different color than the original color on your system

When the computer system is showing different colors of image then what you get after pressing on substrate, it may be due to missing ICM profile. If you don’t have an ICM profile then you should contact your manufacturer for an updated version. Download it to your system and use it.

Another issue could be due to your heat press settings. When you are not using the right amount of heat for your substrate then it may cause the color issue.

5. Design did not transfer to the blank

The most exciting moment for which every crafter waits is when you finally pull off the transfer paper to see a vibrant image on the substrate. Then when you see just yellow residue instead of artwork, it is such a let down. If this happens to you, it could be because of.

- You’re not using high quality sublimation ink.

- The substrate is not having the right amount of polyester material or coating to make a bond with sublimation ink. Always make sure the substrates are made for sublimation work.

- You were not using the right heat settings for proper image transfer. So use an infrared thermometer to check the temperature and make sure it is high enough for the printing process.

- Now allowing enough pressing time. If you are pressing the print for very less time then the image will not transfer properly. There are many substrates which need around 1 minute or higher. Always check the substrate you’re working with and choose time settings accordingly.

6. Bleeding and ghosting

Bleeding and ghosting is a very common mistakes in sublimation printing. Some common causes of these issues are.

- There could be some moisture present on the substrate so when you are pressing it, the moisture prevents the proper transfer of the ink. A simple fix for this issue is you can pre – press the blank for around 10 seconds to make it moisture free.

- Your transfer paper is shifting when you lift open the heat press can result in ghosting. It is because the substrate is still hot enough to accept the ink from the transfer which just shifted or moved. So to avoid it, make sure your transfer is fixed well using adhesive tape so that it does not shift during pressing. Also, you should open your heat press slowly to avoid any movement of transfer paper.

- Always use a blow out sheet for covering your sublimation transfers as the artwork can actually transfer to the platen of heat press which will be then transferred to the next substrate. So, make sure you are always using a clean and new blow out sheet.

7. Light or blank areas in pressed substrate

Whenever you see a light or blank area of the pressed material, it can be due to the uneven heat generated from your heat press or maybe due to the presence of moisture on the substrate. This printing method requires high heat for printing artwork correctly and the presence of moisture prevents this even heat distribution so the artwork is not transferred completely on the substrate. Here are the tricks which I use to prevent it.

- Use an infrared thermometer to check the temperature of multiple areas of your heat press platen to see if there is any cold spot.

- Pre press your substrate to eliminate any moisture content.

- Avoid using teflon sheets as a blow out material as it can trap moisture. You can use a plain white blow out paper for better protection from excess ink.

- Make sure to apply even press all across your press as uneven press can also result in poor printing.

8. Lines are appearing around the design

Substrates which are soft like towel, neoprene, linen and shirt don’t need heavy pressure while pressing. If they are pressed too heavily then the edges of transfer paper may leave a line on these blanks.

This can be easily prevented by using less pressure on the heat press. You can also tear the edges of sublimation paper so it is not a hard solid edge. Also, use the lint roller after heat pressing to fluff up the fiber’s flattened areas.

9. Faded sublimation design

For getting a better print you always need a polyester blend or a polymer coated substrate. Substrates having sufficient polymer content provide beautiful and vibrant prints. Less polyester content fabric provides faded/lighter print which is good for vintage look but not for every design.

10. Blue specks on the material

If small blue specks are appearing on your substrate then it is because of the lint which is heat pressed. The worst thing is that these blue specks are dyed permanently on the substrate and will not be removed even after multiple washes. For preventing it, apply a lint roller on the blank before pre – pressing it and then do it again twice. Make sure to do it more than once.

Conclusion

These are some common mistakes in sublimation printing which as a beginner you may do in your projects. Following the precautionary steps will help you avoid it, and you can get beautiful designs easily. If you are facing any other challenge while doing your sublimation transfer, let me know in comments or you can email me.