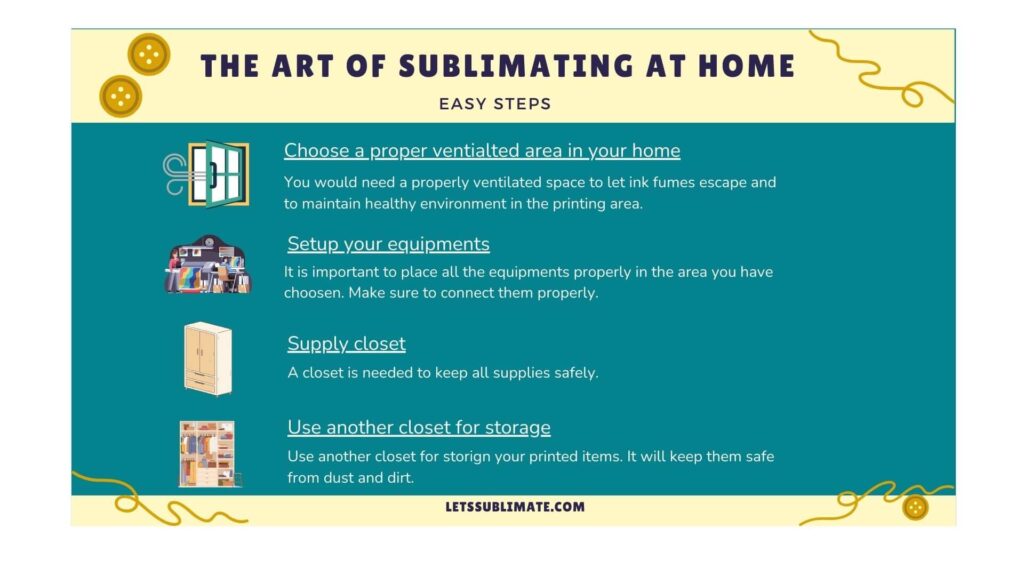

Earlier sublimation printing was difficult because you needed a proper printing press to set up everything as the machines were very heavy and requires lot of space, but now the equipment’s are small, portable and lightweight so you can easily set them up in a room and start your home sublimation work.

Also, if you are interested in small scale production or want to do sublimation as a hobby then setting a home press is the best option. From the comfort of your home you can create a niche market with your personalized products.

Doing dye – sub printing from your home also lets you learn new skills like graphic designing, production techniques, enhancing creativity etc.

My initial printing setup at home included only a few basic things and I printed around 25 t-shirts with it in just 2 days. Yes, you can also set up your initial set of equipment in your home. If you are wondering how? Follow the tips below.

Required tools and supplies for printing

DIY sublimation printing doesn’t need too much fancy stuff. Here is mandatory equipment which can help you to print smudge free vibrant designs.

1. Dye – Sub Ink

Dye – Sub ink is made specifically for the process of heat transfer printing. There are many brands available, and you can choose anyone as per your requirement.

2. Heat transfer paper

This is a specially designed paper which transfers design on your shirt.

3. Protective paper

This is another special paper used to protect the heat press for any ink leakage while printing. Basically it prevents heat press from staining via excess ink.

4. Heat resistant tape

While printing it is necessary to secure design in place and for that heat resistant tape is necessary.

5. Substrate

Always choose high polyester content material (minimum 65% polyester is must) as it will result in a more vibrant print. Remember that sublimation is not suitable for natural fibers like cotton or silk due to their poor absorbent nature and the inability to make permanent prints.

6. Computer system

A system is mandatory to design the prints and then send it for printing. You can work on any computer system, just make sure it is compatible with your design software,

7. Printer

Always choose printers which are specifically designed for heat transfer home printing. These are a bit expensive, but the outcome is amazing. But if you want you can easily convert an inkjet printer to the dye – sub printer.

8. Heat source

A heat press is needed to transfer the artwork from the heat transfer paper to the substrate. It is necessary to use the heat source specially designed for the sublimation. Regular heat source or home use irons will not work as they are unable to reach the high temperatures needed for dye – sub transfer.

9. Lint roller

It is necessary to remove any debris or dirt from the shirt before printing. Here the lint roller will do the job.

10. Cutting machine / Scissors

A cutting machine or scissor is needed for cutting the transfer paper to correct size. There are special cutting machines designed for this but standard scissors will do the job.

11. Software

There are plenty of softwares you can use for creating your designs. You can begin from as simple as a Microsoft Word document and print from there. However if you wish to do any type of customization like resizing the image or adding text etc. then you can use any graphic design software. There are various opinions like Canva, Adobe Illustrator or Cricut’s design space software. Make sure that your final design should have a resolution of 300 DPI for producing high quality print.

How to print images at home on various substrates?

If you are new to sublimation and are confused about what steps to follow for printing designs in different substrates then don’t worry. Here I have mentioned how you can sublimate some common materials at home.

1. Sublimating shirts

Below is the handy checklist with resources, details and tips for making the perfectly crafted shirts at home.

Step 1 – Prepare the design

Begin with a high quality image for a vibrant and clear final outcome. One easy option is to make your designs with softwares like Canva or Adobe Illustrator. These softwares will allow you to create the custom designs from scratch.

It is necessary to consider design placement and size of shirt while creating the design. Another method is to use the existing image.

You can also use your own photo or you can explore ideas online. However, make sure that the image is of high quality and should have a resolution of 300dpi. Remember, higher the DPI the clearer, more detailed and sharper the image.

Step 2 – Print design on transfer paper

Once you are ready with the high quality design, the next step is to print it on the transfer paper using a sublimation printer. Here are the steps for it.

- Begin with loading high quality dye – sub ink and the paper in the printer. You can follow the manufacturer’s instructions for loading paper and ink.

- Now adjust the printer settings where you may need to adjust print quality, paper type and other settings based on the printer and the transfer paper you are using. You can also consult the printer manual or the online resource for guidance.

- Now print the design. Make sure your design is centered and it fits the size of transfer paper you are using.

Note – The design will be mirrored when it is transferred on the shirt, so you should adjust the design accordingly. There are many design softwares which have the option of ‘mirror image’ you can select the option to flip the image automatically.

- Once the design is printed, you should allow the paper to dry completely. Based on the paper and printer, it may take a few minutes or longer.

- Bow trim the transfer paper. You can use a cutting machine or scissors to trim the paper of desired shape and size for the shirt.

Step 4 – Prepare shirt for printing process

- First preheat the heat press, for this you can follow the manufacturer’s instructions.

- Now use the lint roller to remove any type of dirt or debri from the shirt. Hair, lint or any other debri can affect the quality of prints.

- After this place the shirt on the heat press. Make sure it is smooth and flat on the heat press.

- Now pre – press the shirt for a few seconds. It will remove any moisture and wrinkles and result in an even and smooth outcome. It will also make sure that the ink is absorbed during transfer.

Step 5 – Press design on the shirt using heat press

- First position your printed design. Make sure to place it face down on the shirt and secure it with heat resistant tape. Make sure the design is aligned correctly on the shirt.

- Now place the protective paper on the top of your design. It will prevent any ink from transferring to the heat press. It will also protect the heat press from any ink residue.

Note – You can use the parchment paper or butcher paper as the substitute of protective paper as it can prevent ink transfer to the surface of the heat press.

- Now close the heat press and apply required pressure. The recommended settings vary as per the type of heat press and the transfer paper you are using. However the normal range is 385 °F for 45–60 seconds.

Note – Always follow the manufacturer’s instructions for the settings of the heat press and adjust them for best result.

Step 6 – Allow to cool and remove transfer paper

Generally the cooling process takes a few minutes and it is recommended to refrain from handling or touching the shirt until it is cooled completely.

Once the shirt is cooled you should carefully remove the transfer paper. Be sure to be gentle to avoid any damage to print and fabric.

Begin by peeling off from one corner of the paper and gradually working your way towards another corner.

2. Sublimating tumblers

Follow below steps for printing stunning designs on tumblr.

- Initial step will be to design the image with any graphics program like Adobe Illustrator.

- Now print the image on the transfer paper using a dye – sub printer.

- Next set up the tumbler for sublimation by attaching the silicone mat and then cover the tumbler with a protective paper.

- Place the printer transfer paper onto the tumbler and then press the image on the tumbler with the help of a heat source.

- Make sure to use the correct time and temperature for the tumbler and press the design firmly.

- Allow the substrate to cool down and then peel off the transfer paper to reveal a stunning image.

3. Sublimating mugs

Follow below steps for printing stunning designs on mugs.

- First make the design according to the size of the mug.

- Next you need to prepare the mug. Make sure the mug you are using is compatible for dye – sub printing. If your mug has glossy finish, sand it slightly with a grit sandpaper or you can use a mug primer to ensure the image is transferred properly.

- Next you need to print the image on the transfer paper using heat transfer ink.

- Now you have to place the transfer paper on the mug and cover it with protective paper.

- Place the mug in the heat press and press it for suitable time(follow manufacturer’s instructions for the same).

- After pressing, let the mug cool down and then peel off the papers to reveal the amazing design. If the image color is dull then you may need to press it again.

Secret tips about right home sublimation printing technique

With years of experience, I came to a conclusion that tips below matters for every project.

1. Selecting right substrate

While selecting the substrate it is necessary to choose the one which is specially designed for printing. Substrates coated with polyester works best as they are designed for higher heat tolerance, and they offer great color vibrancy. It is also important to note that the substrate you are using should be compatible with the printer being used.

2. Testing

Before initiating the bulk printing project it is necessary to test the output on a small sample of substrate. It will let you resolve any potential issue before proceeding further. In addition, testing allows you to choose an ideal setting for getting high quality results.

3. Storing and handling prints

It is important to store and handle prints correctly. Always keep the prints away from direct sunlight in a cool and dry environment. Also the prints should be handled rightly to avoid any smudging or damage.

Why does my printed artwork look so dull?

So, you have created a perfect design with proper color. You have also checked the printer settings and have mirrored images also. The final print is also of the perfect size. You go to take the print paper from the tray and … ugh. Why does the color look so dull? Why does it not match the design?

What happened?

Well, most likely, it is what has not happened yet.

This special ink is a heat activated dye. The dull design you see on the heat transfer paper will always appear dingy and dull as they have not yet been exposed to the right pressure and heat.

Once the design is transferred to the final substrate under specific heat and pressure, the color will become brighter.

But if the colors are still dull after pressing you may have to increase the temperature of the heat source or increase the pressing time.

If the colors are odd on final output (like brown or green where there should be black) then it could be the result of underbaking or overbaking. For this you should invest in an infrared thermometer as it will help you to make adjustments in temperature of the heat press.

Conclusion

How to print sublimation images at home is quite easy if you follow the above steps. Make sure to have all necessary equipment so that you can easily print amazing designs on the substrates. If you are still not sure what to do. Check out this easy video tutorial.

Frequently Asked Questions

Q – Can I do sublimation printing at home?

Yes, you can easily do sublimation printing at home, all you need is to set up your printing press with equipment like ink, printer, laptop, paper, heat press. Make sure these equipment are of good quality because low quality equipment won’t produce great results.

Q – What home printers can be used for sublimation?

For dye – sub printing there are various printers available and you should use the one which is compatible with your ink and paper. You can also convert a regular printer for sublimation printing. But you should keep in mind that the printer you are getting is of good quality.

Q – Can you print your own sublimation designs at home?

Yes, you can print your own designs at your home press. You can make a high resolution design and DPI more than 300 to get the quality output. Also, the design should be printed with high quality sublimation ink and printer on a polyester or polymer coated substrate under optimum heat and temperature.

Q – What kind of materials can you sublimate on from your home press?

You can print almost every material from your home. Just follow the sublimation printing steps and you are good to go. Some materials which I have sublimated are t-shirts, mugs, tumblers, mouse pads, wooden boards, keychains etc. However, you will not be able to print large materials at your home as the equipments are too small to handle it.