You might be having so many questions about how you can print these stunning artworks on various materials. What is the science behind these masterpieces?

Well, it is no rocket science. All you need is the right knowledge of ink, printers, substrates and the procedure.

If you are new to this wonderful printing technique and want to know how you can make custom designed materials, then don’t worry.

Coming from a printing background and having four years of hands-on experience in dye sublimation printing technique, I am here to explain what exactly it is and how it works. So, follow along.

What is dye – sub printing?

Dye – Sub printing process actually means when a solid material is turned into gas without passing through a liquid state.

So, all – over – printing is the process where solid ink design is printed to a transfer paper and then under specific heat and pressure the design is transferred to a substrate.

This method bypasses traditional printing as the ink does not go through the liquid phase. Also, there is no drying process after final transfer to the substrates.

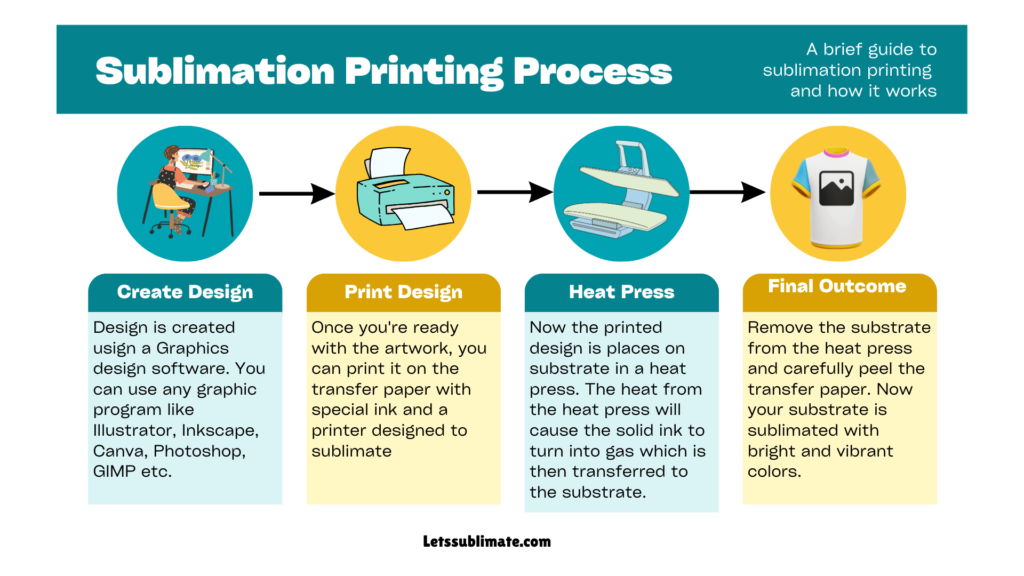

How does sublimation printing technique work?

As per my experience, let me explain the working in simple steps.

Step 1 – Create design

First you need to create a design for printing. You can use any graphic program like Illustrator, Inkscape, Canva, Photoshop, GIMP etc. I personally use Canva and Photoshop as both are user friendly and have lots of amazing features for creating unique images.

Step 2 – Print the design on transfer paper

Once you’re ready with the artwork, you can print it on the transfer paper with special ink and a printer designed to sublimate. I have two Epson printers; one I use with Hippo ink (for vivid and bright prints) and another one with A-sub ink (for anti – oxidation & anti – UV properties and its compatibility with multiple substrates).

Step 3 – Use proper settings

Now you have to transfer this artwork on your substrate using a heat press. Remember settings of the heat press depends on the type of substrate you are using. I recommend consulting the manufacturer’s instructions for using correct settings for every material. Once you have set the pressure, time and temperature you can begin printing.

Step 4 – Placing substrate & transfer paper on the heat press

Next you have to place the substrate on the transfer paper and make sure your design is facing up. It will be best to secure it in place with heat tape. Now apply pressure to ensure proper transfer.

Step 5 – Apply heat

The temperature and time of the heat press will vary according to your substrate. The heat from the heat press will cause the solid ink to turn into gas which is then transferred to the substrate.

Step 6 – Remove substrate and transfer paper

Once your transfer is complete then you have to remove the substrate from the heat press. Next you have to carefully peel the transfer paper and discard it. Now your substrate is sublimated with bright and vibrant colors.

What printing equipment are needed for polyester fabric printing?

I personally begin my journey with below equipment and i feel every newbie must have below supplies to begin with.

1. Printer and ink

A dedicated ink and printer is important for sublimating. There are many specific models however my favorite ones are Epson and Sawgrass printer, and I use Hippo and Epson ink with them.

2. Transfer paper

It is recommended to use special coated paper to print the design as it can hold and then release the ink when heated. Choosing correct transfer paper plays a significant role in color vibrancy, clarity of prints.

3. Design software

Out of many designs software I personally use Canva and adobe as they are user friendly and have multiple features for making custom designs.

4. Blank substrate

The material on which you are printing is known as the blank and it should be compatible with your ink. As a beginner you should prefer using polyester or polyester coating substrates.

5. Heat press

A good quality heat press is mandatory for transferring the designs on blanks. According to your projects you can choose from mug press, cap press or flatbed press. I personally own all as I work on multiple projects and honestly the outcome is amazing.

6. Other important supplies

Apart from the above five important supplies I also use heat resistance tape for securing design while transpiring, protecting paper to shield the products and press and the lint roller for preparing my blank before printing.

How can you choose the right material as a beginner?

Getting started with sublimation as a beginner requires selection of right material for printing. It is true that every material is not suitable for digital heat transfer printing. There are some limitations. According to my experience as a beginner you should go for below preferences.

1. High polyester content

I always prefer using a blank having more than 65% polyester content to get long lasting and vibrant designs. So, it is my recommendation, as a newbie you should look for the blank containing high polyester content.

2. Polymer coating materials

If you want to sublimate non fabric materials like metal sheets, plates or mugs then you should look for the surface having a polymer layer made to accept ink.

3. Quality matters

Always remember, the quality of the substrate is directly proportional to the final outcome. So, always invest in high quality material and make sure the output looks best.

What is the science behind heat transfer printing?

This printing includes a scientific process which seems like magic, but it has its roots in chemistry. It begins with dye particles which are transferred to gas using pressure and heat, bypassing the liquid phase entirely – this process is known as sublimation.

Imagine a block of dry ice turning into the fog without becoming liquid – this is similar to how the printing method works.

When heat is applied to dye, the particles are then converted to a high – energy pack which bonds to the polymer present.

As soon as the heat source is removed, the dye then turns back to solid and now it is embedded in the fibers of polymer, ensuring the image won’t degrade or wash away over time.

This wonderful transition from solid to gas and then back to solid is the cornerstone of dye – sub printing and is what makes it so efficient for making long – lasting prints.

Pros & cons of dye – sub printing

The printing technology is popular for its durability and high-quality results has its both advantages and disadvantages. Let’s check out.

Pros

1. Versatility

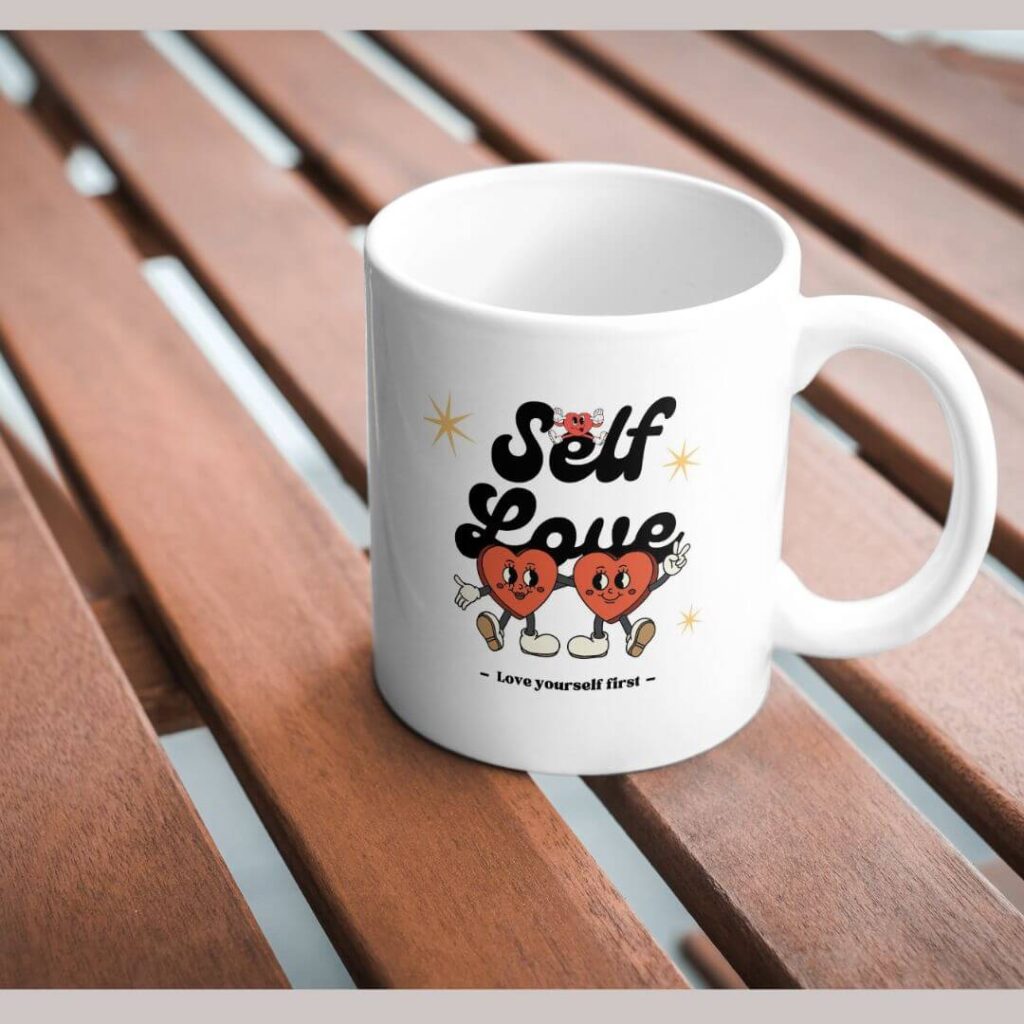

The printing method can be used on multiple materials like metals, ceramics and fabrics. Which makes it an ideal choice for a huge range of products from accessories and clothing to keychains and mugs.

2. Color Fidelity

The method offers superior vibrancy and color accuracy. The high tone of the color achieved in dye sub printing results in the stunning image with smooth gradations.

3. Image longevity

Images created are known for their long-lasting nature. The process turns dyes in gas which then make a permanent bond with fibers of the material. The print is less prone to fading over time.

4. Consistent tone

Every dot of ink offers a consistent tone to every material it touches. The design offers a high-resolution look which features the distinct appearance on every substrate.

5. Less drying time

After completion of the project, you do not have to wait for the fabric to dry. You can simply remove the material from the heat press and fold it up without even worrying about smearing.

6. Less energy

The heating system involved in digital printing does not need extensive energy, nor does it require any outside water or ink. You only need the press material which you are going to use.

7. Create a more detailed image

If you think digital printing is for printing simple images. No, you can easily print more detailed designs. The printer can print highly layered designs with multiple colors.

Compared to traditional printing methods, dye sublimation generally proves superior in its ability to offer high quality photographic prints which are durable and touch friendly. They won’t crack or peel after multiple washings.

Cons

1. Color shifting

Due to inconsistent pressure and temperature, you might experience inaccurate colors printed on the substrate. Regular calibration of the heat press and printers is needed to maintain color accuracy.

2. Gassing out

The ink can sometimes gas out prematurely when it is stored improperly or if it is heated excessively. Using the quality inks and by maintaining optimal storage conditions you can prevent this.

3. Ghosting

During transfer of artwork if there is any movement between the substrate or paper then it can result in blurry image causing ghosting. It is recommended to secure the artwork with heat resistant tape to prevent ghosting.

4. Only light-colored substrates are best for printing

Dye – sub printing does not work well on dark substrates. However, you can apply a separate polymer coating on dark color blanks to make it work, but it may not be as effective as prints on light colored objects.

5. Slow printing process

The printing process is a bit slower as on an average you can produce 60 pieces via sublimation. However, the longer time duration is due to the fact that it produces more durable and detailed layouts.

These issues can be easily eliminated with proper control on the process including timing, pressure and heat along with high quality equipment and inputs.

What materials to avoid sublimating as a beginner?

Sublimation for beginner may see, difficult but with little practice you can easily master it. There are certain recommendations which needs to be followed for choosing the substrate. So, here are some fabrics which I suggest avoiding in initial phase of your journey.

1. 100 % Cotton

The very common material which you should not use in your printing projects is 100% cotton. The issue is because of the atomic makeup of cotton or similar fibers which does not allow the dye ink to permeate its structure in the needed way to create a long – lasting and crisp image.

2. Black/Dark fabrics

Other fabrics which you should not use are non-coated items, black fabrics and dark materials. You can definitely sublimate them, but I recommend not to do it in the initial phase of your journey. If you want to give it a try, use the light colored under base like white vinyl to print the designs.

3. Non – Coated Items

Many non – coated items will never allow the ink to permeate the surface and will also result in poor results. The only solution to print on the uncoated items is to apply the coat. Doing so will permit the inks to permeate the layers of fibers. For products like ceramic mugs, you should use the coating of polyester before sublimating.

My favorite designs which work well with dye – sub printing

If you are a beginner and cannot figure out which design you should choose for your projects. Then here are some ideas which you might consider.

1. Photographs

So, when I run out of ideas I always use photographs for my projects. You might be having some high-definition images in your photo gallery. Go for it, but make sure the images are in CMYK format.

2. Solid colors

Most of the time I choose vibrant and solid color printing as the outcome is accurate and clear.

3. Vector graphics

If you are printing a huge image, then consider graphics which are made of shapes and lines as they can be scaled to any size without giving up quality. This is another stunning idea which I use when I want to experiment something new.

4. High contrast designs

Lastly, I go for high contrast designs with exceptional sharpness and vibrancy like bright/ black and white colors. Trust me, the outcome is very attractive, and you are going to love it.

Designs which I consider less for printing

I personally prefer not to use below two design formats as the outcome is not so good. However, you can feel free to try them out.

1. Images with very fine details

If the images have complex patterns, fine details or small texts then I prefer not to use them as it may not print properly on the substrate.

2. Images with gradients

Gradient images generally produce distorted outcomes when sublimated. It will be better to avoid these kinds of designs.

Applications of sublimation printing

With almost three years of experience I can say, this printing method has many applications in the modern world. Let’s check out some best places where it is best suited.

1. Apparel & fashion industry

All – over – printing has brought a revolution in the fashion and apparel industry by providing unlimited design possibilities. It has open doors to make unique and vibrant patterns, graphics, and images on clothes including dresses, swimsuits, t-shirts and much more.

2. Merchandise and promotional products

The miraculous printing method is highly used for making promotional products and merchandise. It also permits businesses to print their brand messages, slogans or logos on multiple items like phone cases, keychains, mugs, tumblers, t-shirts etc. This high-quality print helps in brand recognition and of course promotion.

3. Interior design and home decor

Sublimation has found its place in interior design and home decor. It is one of my favorites. I love creating custom designs on different items like ceramic tiles, wallpapers, curtains, cushions and much more. I have myself created personalized living spaces for various people. Trust me it works like magic by offering a unique ambiance.

4. Sports and team uniforms

My other favorite part is creating sports and team uniforms as I love to work with intricate designs, team logos. The outcome here can withstand repeated washing and intense physical activities without giving upon quality.

Latest trends and future opportunities

Speaking of trends, heat transfer printing technique has lots of future opportunities and I believe slowly it will bring a major change in the printing industry. Here are some points you should read.

1. Eco – friendly substrates

Due to increased environmental concerns, there is a high demand of eco – friendly materials. You will be happy to know that manufacturers are developing more sustainable materials like organic cotton, bamboo and recycled fabrics. Due to this the printing technology is going to sustain for a longer period of time.

2. All over printing

The printing technique where the design covers the entire surface of the substrate is becoming popular. This method creates immersive, eye – catching designs which stand out in the apparel and fashion industry.

3. Personalized home decor

Nowadays people prefer to spend most of the time at home so personalized home decor things are becoming popular. Dye – sub printing is best for making customized curtains, pillows, blankets and furniture upholstery. Isn’t it amazing!!

4. Small batches and limited editions

Now every individual needs an exclusive and unique product. With this printing technique you can produce small – batch or limited – editions of custom items, catering to collectors or niche markets.

3 Useful tips for successful heat transfer printing

I personally recommend below three tips for getting the best result.

1. Design preparation

The initial and very important step for best printing is to make the design. It includes making digital images with the help of designing tools like Photoshop, canvas. Always remember the limitations of digital printing like resolution and color gamut. Here are some personal tips.

- Use high resolution and quality images. Minimum 300 dpi is preferred for best prints.

- Select the image colors which are within the CMYK color gamut for avoiding color shift while printing.

- I recommended using the color management system to ensure accurate color production.

- Always mirror the image horizontally for creating the mirrored image which can be transferred correctly on the substrate.

2. Preparing substrate

The materials used in printing have a critical role in final print quality. Here are my personal tips you can use.

- Always go for high quality transfer paper which is compatible with the ink and printer.

- Make sure the substrate to be printed is free from any finishes or residual coating. This is important when the fabric is pre – treated for removing any sizing, dirt or chemicals.

3. Tips for heat press

This final step includes transferring design from paper to the substrate using pressure and heat. Some useful tips will include.

- It is important to set the heat press with the correct time and temperature for the material being printed. You can consult the manufacturer’s guidelines for right settings.

- Make sure the blank is properly aligned on the heat press for avoiding any type of distortion or shifting during the transfer.

- Too much pressure is not required. Always use firm pressure to ensure transferring of ink completely on the material.

- For avoiding any tearing or smudging of design, you should remove transfer paper carefully.

Innovative applications you can try as a beginner

To my friends who are always eager to do something innovative. Dye – sub printing has lots of advanced applications. My personal favorite ones are.

1. 3D sublimation

This printing method includes applying artwork to three dimensional objects like figurines, mugs or phone cases. There are special 3D molds and machines which allow seamless printing on curved surfaces which results in unique and eye – catching products.

2. Sublimating dark fabrics

Initially the printing was best for light colored materials, however special ink has made it possible to print artwork on dark surfaces too. This has opened up new and exciting opportunities in fashion industries allowing for detailed and vibrant designs on colored or black apparel.

3. Soft signage

Due to portability, lightweight and visually striking displays, trade shows, events and business use sublimated fabric backdrops, flags and banners. Compared to traditional signage these are easy to store and transport.

4. Sublimating ceramic tiles

Now interior designing can be done in a much better way with sublimated ceramic tiles as they can be used as decorative wall art, bathroom accents or kitchen backsplashes. This technology allows for high – resolution and intricate designs which are both aesthetically pleasing and durable.

Tricks to make your sublimation artwork look more vibrant

Vibrant prints are loved by everyone, but there might be instances when your print goes wrong and the outcome is dull. Here are the best tricks which can be used to achieve vibrant looking prints.

Experiment with different settings. Yes, settings vary from one substrate to another. It is my recommendation to check manufacturer’s guidelines, but if you are still not satisfied like me (most of the time), go for various setting experiments. So, try using different combinations of heat press settings, ink, paper, printer settings, design space, temperature and time until you get the results you are looking for.

Conclusion

Dye – Sub printing is the new trending way to showcase your artwork on uncountable substrates. With its eco – friendly equipment more and more people are now adopting it. Not only this, but the technology also assures to provide durable, versatile and vibrant outcomes which can be printed on any material.

If you are new to this technology, then you should follow above complete guide to sublimation printing. But, if you are still confused and want to know more, check out this video by one of my friends. If you still have any questions and want to connect with me, send me a message or comment below.

FAQs

Q- How long does sublimation print last?

If proper care is taken, these prints can last for years as the print makes bonds with the fabric on which it is printed. However, if you are not taking right care of the printed substrate then the design will fade away soon. So, make sure to store the printed item away from direct sunlight, use mild detergent to wash it and do not directly iron on the design.

Q- Is Dye – sub printing expensive?

If compared to other printing methods it is not much expensive, however it includes initial setup cost. Initially you have to buy a sublimation paper, printer, ink, substrates, and a heat press machine to start printing your designs. Once you have these items working then there is not much investment in printing substrates.

Q- Can I sublimate curved or uneven surfaces?

Using a heat press with adjustable pressure is best for printing on curved and uneven surfaces. However, you should use the right heat press settings to achieve the desired outcome. Also, you should have polymer coated or polymer substrates for better ink bonding.

Q- Can you sublimate cotton fabric?

Sublimating directly on cotton fabric is not possible as the fabric is not designed to hold the colors, but you can use cotton blend or polymer coated cotton to print designs on it. Remember that cotton is a natural material, and its fibers does not make bond with the dye – sub ink. So, always use polymer layer before printing.

Q- Can I sublimate on dark colored items?

No, all over printing is only meant for light colored items, however you can apply a polyester coating before printing dark substrates. Creating a polyester coating on dark substrates make sure that the material accepts the ink and make permanent bond with it.

Q- Can I use regular ink and printer for printing?

No, digital printing requires special ink and a printer. The ink is specially made to handle high pressure and temperature. Also, the method is design to print with special printer which are compatible with sublimation printers. So, make sure to use high quality sublimation printer and ink for your projects.

Q- What is sublimation printing best for?

The printing method is best for producing full color and vibrant images in multiple substrates like metal, textiles, plastic and ceramics. The method is often used to make personalized gifts, promotional items and custom apparel.

Rattling nice style and superb content material, hardly anything else we want :D.

Thankyou. I always try to make things easy to understand.

I am a beginner, and I wanted to learn about sublimation printing. Your article is perfect for understanding everything about sublimation.