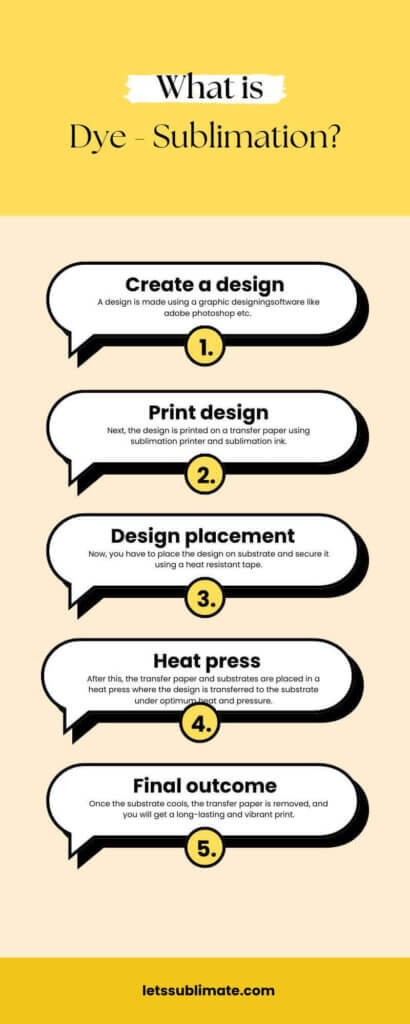

Dye Sublimation is a type of printing where heat is required to transfer the dye onto the material. This complete process includes printing artwork on special transfer paper using the dye–sub ink.

When the design is created and printed on the transfer paper, it is then placed on the substrate. The transfer paper and the material are then placed in the heat press, where both pressure and heat are applied to the transfer paper and causing the dye to sublimate.

During the process, the dye turns into gas, and the heat from the heat press encourages the porosity in the substrate, due to which the dye in gaseous form can penetrate the surface effectively. After the desired time, the dye gas effectively penetrates and makes a bond with the material fibers before it turns to a solid state.

This is how the dye sublimation makes your artwork become a permanent part of the substrate. This process results in very high-quality, vibrant, and long-lasting prints.

What Is Sublimation Printing?

This printing technique allows the ink to transfer to the substrate directly. A special printer is used to produce high-quality prints using the thermal printing technique. When the printing ink gets heated, it vaporizes and then converts to gas, diffusing on the substrate and making a permanent bond. This method is used in various places, including custom designs and creating industrial components.

How Does Dye–Sub Printing Work?

Dye sublimation printing works only on specially coated surfaces, including metal or ceramics, and it can also be applied directly on fabric. It uses heat to transfer dye on the substrate and generates a print that will not crack, peel, or fade over time.

This process begins with making a digital design, which is then printed on transfer paper using sublimation ink. This transfer paper is then secured on the substrate using the heat-resistant adhesive.

Now, this sandwich of substrate and transfer paper is placed in a heat press where heat and pressure are applied, causing dye to sublimate, i.e., it turns into gas.

The heat from the heat press machine also opens the pores of the substrate, due to which the ink in gaseous form is able to penetrate the substrate and make a permanent bond with the material.

When it cools down, the ink in gaseous form re-solidifies, and now it is a permanent part of the material.

What Materials Are Suitable For Dye Sublimation Printing?

It is a versatile printing method, but you can generate successful prints only when the material used is right. Not every surface can effectively hold the sublimation ink, as the printing process needs specific properties to make the bond with the dye permanently. Here is a list of substrates that are best for this printing technique.

1. Polyester fabric

Polyester is the best material for dye–sub printing because the molecular structure of polyester permits the ink to bond permanently during the process. You can generate long-lasting and vibrant prints on this material. Substrates having at least 65% polyester content are the best blends.

But why polyester?

Because the ink penetrates the fabric instead of sitting on the surface, ensuring the design won’t crack, fade, or peel over time.

This material is widely used to make active wear, hoodies, t-shirts, sportswear, curtains, pillowcases, cushions, etc.

2. Polymer-coated hard surfaces

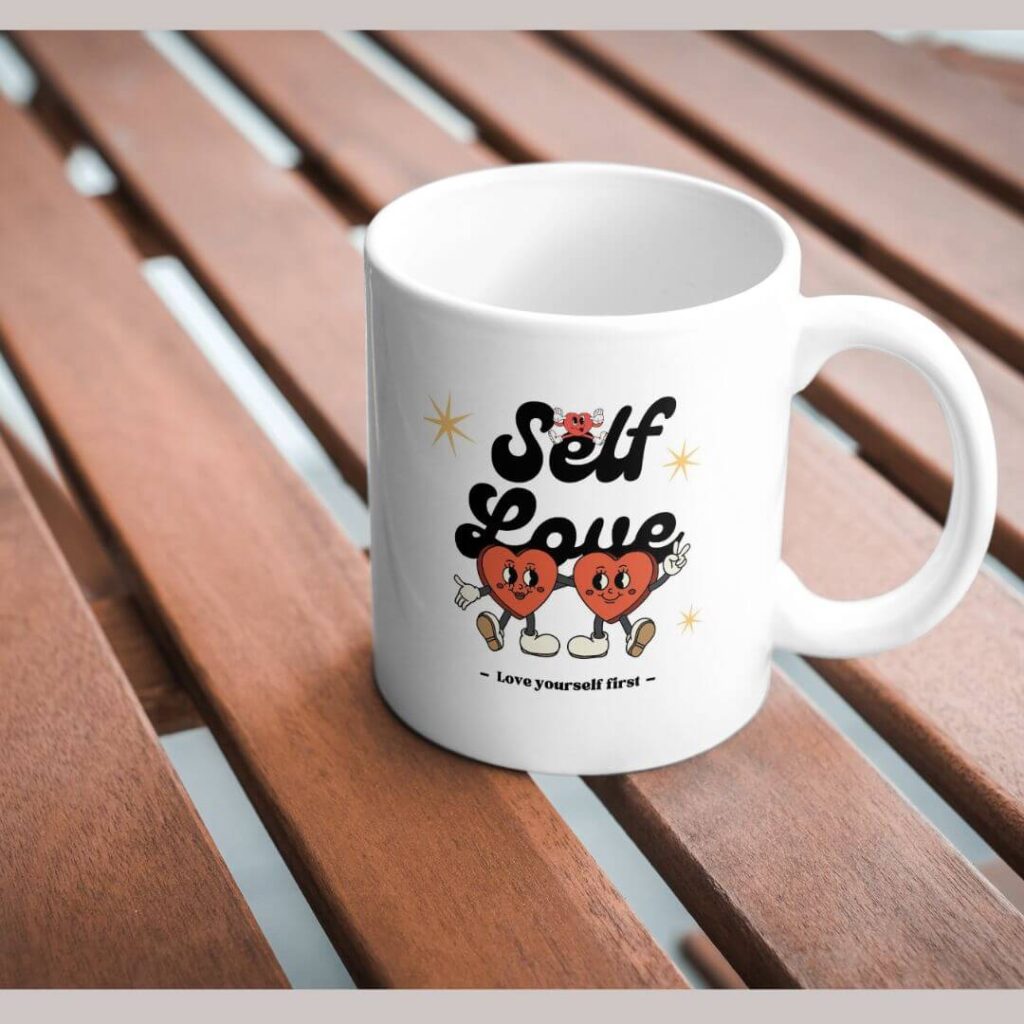

Hard surfaces like glass, ceramics, and metals need a polymer coating to work with the dye sublimation process. This coating offers the substrate the necessary bonding properties to hold printing ink effectively. The ink will not make a permanent bond without a polymer coating, which results in poor or incomplete prints. Substrates like personalised tumblers and coffee mugs, high definition photo panels made from ceramic or metal, and promotional items like coasters or key chains are some common examples of polymer-coated hard surfaces.

3. Blended fabrics

Fabrics that are a mix of other materials and polyester can also be used for this printing method; however, the polyester content should be more than 65%. Remember that the lower the polyester content, the less durable and vibrant the prints will be. These polyester blends are mostly used for uniforms that need added stretch or comfort.

4. Blanks

Sublimation blanks are pre-made substrates that are purely designed for this printing technique. These are made from polyester or are coated with polymer for the right outcome. Metal plates, ceramic plates, tote bags, mouse pads, and awards, pre-coated, are some examples of dye-sub blanks.

5. Rigid polymeric materials

Pure polymer-based materials like some plastics and acrylic can be directly sublimated and are mostly used for ID cards, signage, and lightweight promotional items. These materials are durable and offer the right color retention, which makes them ideal for high-use or outdoor items.

What Are The Benefits Of Sublimation Printing?

Now you have understood what is dye sublimation, let’s check out the various benefits of this amazing printing process.

1. High-quality prints

It results in high-quality prints in a detailed and huge range of colors. The technique can be used with the most intricate of designs and provide precise color matching.

2. Durability

Sublimation printing yields incredibly durable prints, which means they are resistant to issues like peeling, cracking, or fading.

3. Versatility

The technique can be used for printing on various items like rubber membranes, metal, plastics, and silicone membranes.

4. Customization

This method is easily customizable, which makes it the best option for personalized items and designs with minute details.

5. Eco–friendly

The process offers – friendlier alternative compared to traditional printing methods and produces very little waste. The process also uses less water and energy, producing fewer overall emissions.

Conclusion

Dye–sub printing is the best printing method, which offers a vibrant and durable outcome. It is also an environmentally friendly option that produces fewer overall emissions. If you want to know more about this printing method, then you can click here. If you still have some unanswered questions, then you can comment below or you can email me.

Frequently Asked Questions

Q – How long does sublimation printing last?

Sublimation printing is an innovative method that allows us to print detailed designs on multiple materials. When they are properly cared for, the prints can last for multiple years without fading, peeling, or cracking. So, make sure to use proper washing and drying instructions for a lasting print.

Q – Do you need a special printer for the dye–sub method?

As the ink used in this process turns gas from solid without passing to the liquid state, it would need a special printer which are purely designed to handle the dyes used in the process. You can also use a home printer, but that needs to be converted to a sublimation printer.

Q – Is sublimation suitable for photo printing?

Yes, you can use the dye–sub technique for photo printing as it offers high definition, sharp, and vibrant colours.

Hello very nice website!! Guy .. Excellent .. Superb .. I will bookmark your blog and take the feeds additionally…I am happy to seek out so many helpful info right here in the publish, we want work out extra strategies in this regard, thanks for sharing.