Customizing leather products is very common nowadays and I am also impressed with the results. So, I thought of trying it and making a customized bag for myself. With few hit and trial I got the result I wanted. If you want to know the exact technique of sublimating leather then follow along.

What leather can you sublimate?

Luckily you can sublimate both natural and faux leather and make customized art pieces. However, you need to prepare the substrate before printing the artwork. The processing of printing is very simple and includes only few steps.

Different types of leather

Leather is a flexible and durable material which is used is making various items like shoes, wallets, furniture, and clothes. There are two types of leather i.e. faux leather and genuine leather and the best thing is that you can easily sublimate both of them.

1. Faux leather

Faux leather, synthetic or imitation leather is a man-made material which looks and feels like original leather, but it is not made from animal hide. Generally it is made from synthetic fabrics or polyurethane which is treated to look and feel like original leather. This leather is used to make bags, clothing, furniture and accessories. It is the best alternative of real leather.

2. Genuine leather

This leather is made from the hides of animal and is comparatively more expensive and durable than faux leather. It is much more breathable and durable than other leather. Natural leather has unique look and feel and with proper care it can last for long time.

How to choose natural leather for sublimation process?

Here are the tips which I personally follow to get the right type of natural leather for your printing work.

1. Select lighter shade of brown

Original leather is available in multiple shades of brown. It will be best if you choose a lighter shade of brown for your project. Lighter shades are best because the colors of the final output will be more vibrant. Chances of discoloration and fading will also be reduce because of a lighter base.

2. Choose a smooth surface material

Select the substrate with a smooth finish instead of coarse surface because smoother finish will ensure the design to print properly on the material. But on coarse surface, yoru design may not penetrate properly.

3. Cut the substrate

You should always cut the leather material I appropriate size if it is in pre – cut form. Always use leather cutting knife, scissors or rotary cutter for cutting the leather in required shape and size. The tool you will use to trim the leather material is based on the thickness. So select it wisely.

Can you sublimate on faux leather?

Yes, you can easily sublimate on faux leather. The material is highly receptive to sublimation ink as it is made of polyurethane or other synthetic material. The prints are eye catchy and vibrant. It is a prefect alternative of genuine leather and best for sublimation. Also,

1. It is available in precut designs

The faux leather is available in various shapes and designs. It means you can get the substrate according to your choice and can print it directly.

2. Sublimation paper is available in white color

Transfer paper is available in white color which allows you to produce vibrant prints. This paper also ensures accurate color and crisp image quality.

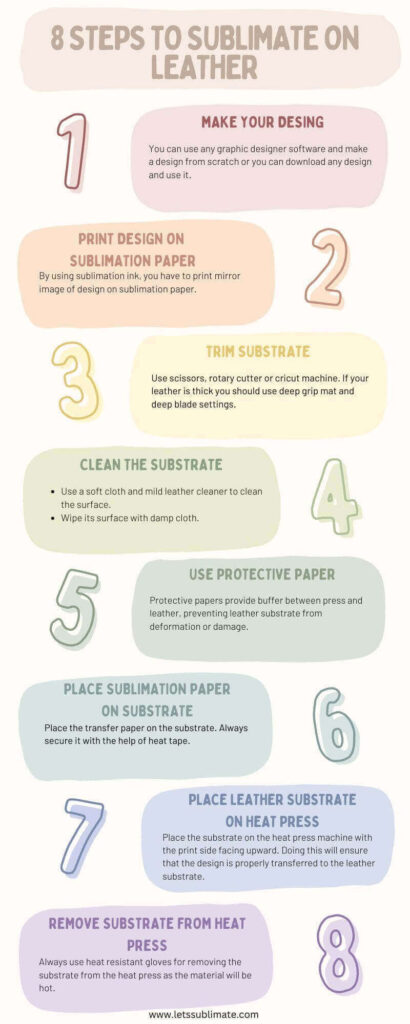

Can you sublimate on leather – Easy steps

Although the process of printing leather is simple but require special care and attention to get desired outcome. For successful sublimation on leather, you can follow the below steps.

1. Make your design

First you need to create a design. For this you can use any graphic designer software and make a design from scratch or you can download any design, modify a bit and use it. But make sure the design is of high resolution and it should be minimum 300 DPI. Because good quality designs will result in better prints.

2. Print design on sublimation paper

Now with the help of sublimation ink, you have to print the design on transfer paper. Always print mirror image as the leather is not transparent. Select the mirror image option while printing the image on transfer paper so that the image can correctly transfer to the substrate.

3. Trim the substrate

Based on the project, you should cut the leather to appropriate size. For this you can use scissors, rotary cutter or cricut machine. If your leather is thick you should use deep grip mat and deep blade settings. If you are confused, how to do it. Follow below steps.

- Measure the size of design and draw a line with the help of ruler.

- Not secure leather firmly on a cutting mat or the flat surface.

- Now use a sharp rotary cutter to cut along the marked line. Always apply even pressure and always keep blade parallel on the surface for getting best result.

- Now clean up the edge of the leather with fine grip sandpaper to get smooth finish.

4. Clean the substrate

For better penetration of sublimation ink in the leather material, you should properly clean it. Follow below steps to clean the material properly.

- Use a soft cloth and mild leather cleaner to clean the surface of material.

- Wipe its surface with damp cloth for removing dirt and dust.

- To protect it from any damage you should apply leather conditioner.

- Once the conditioner is dried, use a lint free cloth to buff the surface.

- Last use the adhesive remover for removing any adhesive residue from the material.

5. Use protective paper (butcher paper) on heat press panel

Next you have to place a butcher paper on the heat press platen, before placing the substrate. This will help to protect any potential damage caused by the substrate and also offer a smooth cutting surface. You can also use other protective sheets like parchment paper, Teflon sheets etc.

These protective papers provide buffer between press and leather, preventing leather substrate from deformation or damage due to direct connection with digital press.

These sheets also help of heat spread evenly and also lower the risk of hot spot which can cause discoloration on the substrate. They also prevent ink from smearing on the panels and help to keep the subli press clean,

6. Place sublimation paper on substrate

Now you have to place the transfer paper on the substrate. Always secure it with the help of heat tape. This tape will prevent the paper from moving during the process of sublimation. Make sure to cut the paper according to design before attaching it to the substrate. To ensure a secure attachment, press it down firmly.

7. Place leather substrate on heat press

Now place the substrate on the heat press machine with the print side facing upward. Doing this will ensure that the design is properly transferred to the leather substrate. Make sure to use the protective sheet as mentioned above to prevent leather from sticking to the heat press platen.

Using optimum temperature and pressure press the design on the substrate. Always begin with lower temperature for short duration while sublimating leather. I recommend starting from 320°F for about 20 seconds.

You can increase the settings if you are not satisfied with the result. But the optimum temperature for leather is 380°F which should be applied for around 50 seconds to get the best result. Pressure settings should be medium.

8. Removing the substrate from heat press

Always use heat resistant gloves for removing the substrate from the heat press as the material will be hot. Let the material cool down before further handling. Remove the transfer paper and congratulation; you just completed your leather printing project.

Conclusion

Printing leather is the best way to add personal touch and uniqueness to your projects. With correct method and creativity you can easily product beautiful designs on leather. Follow above guidelines to get the best outcome. If you have any question you can comment below or you can message me directly.

FAQs

Q – What material do you need for sublimating leather?

You need basic material like heat press, transfer paper, printer, ink and a substrate.

Q – Which leather is best for sublimation process?

Faux leather and original leather are best for printing. Do not use any other leather as they are difficult to press.

Q – Can you sublimate on leather patches?

Yes, you can print artwork on leather patches by following leather sublimation process.

Q – What are common issues while sublimating leather?

You may encounter issues like distorted, faded designs, adhesion problems and challenges with temperature of heat press. Make sure to do some testing before printing final substrate.