If you love to make personalized products with unique designs then sublimation on glass is a wonderful option as it offers vibrant outcome, durability, uniqueness, personalization, professional appeal, versatility and they are also eco- friendly.

Printing on glass combines artistry with functionality, allowing creativity while producing durable and high quality items.

The process of glass printing should be done carefully and too much pressure and temperature from the heat press can break the glass. To know about the right way of printing glass, continue reading.

Can you sublimate on glass substrate?

Yes, sublimation printing can be done on glass substrate, however not all types of glass material can be printed. Glass substrate needs to be specially coated to accept sublimation ink.

This special coating on glass helps to hold the ink during the printing process and make sure that the image gets transferred on the glass properly.

Once the glass blank is coated, then you can begin the printing process which includes

- Printing the art work on the transfer paper using the special ink.

- This paper is then placed on a substrate and then heat & pressure is applied using a heat press machine.

- The heat & pressure cause the ink to transfer.

- When glass cools down, the ink then re-solidifies and makes a permanent bond with the glass.

Note – It is important to use the high-quality transfer paper and ink which is specifically designed for glass printing to get best results.

Challenges to print glass and how to overcome them

Sublimation on glass is not always smooth. But there can be some issues along the way like artwork not sticking, uneven ink transfer etc. But do not worry as most of these challenges can be easily tackled.

You can overcome these issues by ensuring that your glass is super clean and then apply a white coating for sublimation. While sublimating you need to keep pressure and heat consistent to get the best result.

But if you are still facing any issue, you need to tweak the heat press settings to find the right results.

Materials needed to sublimate glass

For printing on glass you should have the below equipment.

1. Printer

This is the very first requirement for printing. Get a printer which can print both on right and reverse settings. Also, ensure these printers deliver high quality prints.

2. Transfer paper and Inks

Sublimation on glass needs high quality paper and ink. It will be better to choose the same brand of ink for perfect quality and compatibility.

3. Glass blanks

While buying glass blanks you should get tempered glass having white opaque background to make sure that you get perfect reflective quality.

4. Heat press

Sublimating glass is tricky and you need a heat press which is specially made for glass substrates.

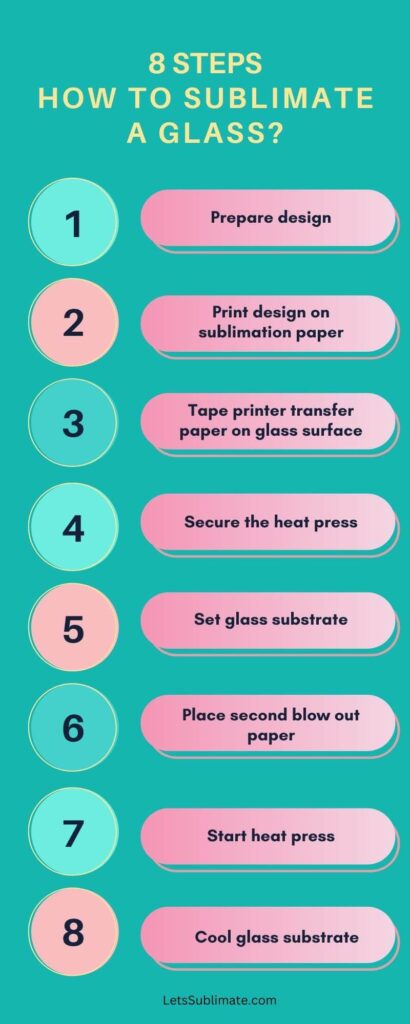

8 steps for glass sublimation

To simplify the process of printing glass here is the step-by-step procedure to print on glass.

1. Prepare design

First you need to prepare the design for printing on the glass. It can be designed from scratch or you can download a pre-made design from the internet and then customize it for your use.

2. Print design on sublimation paper

After creating a design you need to print it on sublimation paper using ink and printer. Ensure that the design is printed with high accuracy.

3. Tape printer transfer paper on glass surface

After printing the design on transfer paper you need to stick it to the substrate using adhesive tape.

4. Secure the heat press

After securing the design you need to secure the heat press using a blow out paper. This blow out paper will absorb any ink leakage and save your heat press platen from any ink leakage.

5. Set glass substrate

Now put the glass blank on the blow out paper in the heat press for preventing it from the damage. Make sure the transfer paper should face down to get better results.

6. Place second blow out paper

After setting the glass plate you need to place the second blow out paper on top of the glass to prevent damaging heat press from excessive ink.

7. Start the heat press

You need to set the heat press temperature at 400 degree fahrenheit and then heat press the substrate for three and half minutes with medium pressure. Remember not to apply too much pressure as it can break the glass.

8. Cool the glass

You need to carefully remove the blowout paper from the top of the glass and then remove sublimation paper and let the glass cool completely. After cooling you will see a beautiful replica of your artwork.

How to deal with image clarity issues?

The most common issues which you may face while printing a glass are the image clarity issue. It can happen if you are not using the right heat press settings or if the glass you are printing is not clean enough.

To avoid this issue, ensure that you are using the correct heat press settings for the printing and also ensure the substrate is clean.

For cleaning you can use a lint free cloth along with isopropyl alcohol. Also make sure the glass is dry before sublimating. Additionally you can use a glass cleaner to ensure that there is no fingerprint or smudges on the substrate.

How to get durable prints on glass?

Another issue which you may face during glass sublimation is durability concerns. It is true that printing on glass is not as durable as printing on other substrates like ceramic or metal. It is because glass is a porous material which means that dye – sub ink can fade or wear off over the time.

To make sure that your prints on glass last longer, avoid using abrasive cleaners or harsh chemicals on sublimated glass. Also, you should use sealant or a clear coat on the glass to protect the image.

Conclusion

With the help of the above method you can easily print beautiful designs on glass. But make sure the glass substrate you are using is ready to accept sublimation ink. If your glass is not prepared properly for dye – sub printing then you may not get the desired result. If you have any questions let me know in the comments or message me.

Faqs

Q – Can you sublimate on glass mugs and cups?

Yes, you can print on glass mugs and cups. Sublimation printing works on glass tiles, plates, mugs and other items. Just make sure the glass surface is clean, dry and doesn’t have wax or oil on it. After this follow above mentioned steps to print stunning designs on your substrate.

Q – Can I do sublimation printing on a flat glass surface?

Yes, you can easily sublimate on a flat glass surface. Make sure that the glass you are printing is clean and ready to accept dye – sub ink. If the glass is not clean, then it will result in bad prints and can also damage the glass.

Q – What is the ideal glass sublimation temperature?

The ideal temperature ranges from 400 to 420 degrees Fahrenheit. This is the ideal temperature range for printing the glass. Temperature less than this will not let you print the design on glass and if the temperature is more than it may break the glass or result in image ghosting.

Q – Is sublimation on glass permanent?

Yes, printing on glass is permanent however you need to keep few important steps in mind before beginning the process. First you should buy a tempered glass having white opaque background, as the image is better visible on these types of glasses. Next you need to clean the glass before printing and dry it completely and after printing you have to coat it with sealant or clear coat to protect the design. Remember, if you are trying to print on any other glass, then there are chances that you may not get quality prints, and it may fade away with time.

Q – Can you sublimate actual photos of your kids/family members on glass?

Yes, you can easily print your kids/family photos on the glass substrate. You need to follow the same procedure which is used in printing any other high-quality design. Just make sure the photo is of high quality, and you are printing it on tempered glass.

Nice blog here!

Your article provide detailed information about how easily sublimation on glass can be done. This step-by-step process has helped me to print stunning designs on my glass substrate.

Glad to hear that. Hope the prints are amazing. If you want to know more, let me know.

You have hit the mark. It seems to me it is very good thought. Completely with you I will agree.